Portable Poultry Feed Pellet Mill Enjoys High Popularity in Nigeria

High population growth and growing income lead to increasing demand for poultry products in Nigeria. The poultry industry has emerged as the most commercialized and fastest expanding segment in the animal husbandry subsector, which attracts farmers, businessman and more people to invest into poultry industry or raise chickens, ducks, etc. (Read more: Cattle Feed Plant Equipment Price >>)

Nigeria Poultry Feed Pellet Business

However, Nigeria poultry industry still faces many problems, like shortage of funds, small capacity and poor product quality, unscientific feeding and more. And more and more poultry farms adopts pelleted feed to improve the growth and quality of poultry. To save the cost and get more interests, it is highly recommended to make poultry feed pellets by yourselves if you are now or plan to engage in poultry farming in Nigeria.

Buy Portable Poultry Feed Pellet Machine in Nigeria

To make your own poultry feed pellets, poultry feed pellet machine is necessary to improve the production efficiency. There are kinds of feed pellet mill machine for animal feed pellets making, and flat die pellet mill is the most cost effective portable feed mill for breeding farms, poultry farms and small to medium feed pellet manufacturing plant.

Small Portable Poultry Feed Mlll Machine for Sales

According to different requirements, portable poultry feed mill machine can be driven by electric engine, diesel engine, PTO and gasoline engine. You can choose one based on your actual needs. For detailed price and machine parameters, please contact us to get the product catalogue or customized plan for poultry production in Nigeria.

The poultry feed manufacturing process of this portable poultry feed mill, based on the gap of the material powders, reduce the gap of the material powders and form them into pellets with high density and strength under the effect of temperature, friction and pressure. According to the different state of the material, the chicken feed pellet mill is divided into three parts, including the feeding part, extrusion part and forming part. And the key part is the extrusion part consisting of pelleting die and pressing roller.

Superiority of Poultry Feed Pellet Mill

- This chicken feed pellet mill, with small size, simple structure and low noise, covering a small area, is easy to install, operate and move.

- Easy to maintain. You can inspect and find the trouble easily through the feeding port, thus shoot the trouble easily.

- Low cost. The chicken feed pellet press is configured with high quality components, especially the key components, reducing the maintain cost of the Nigerian people.

- The finished pellets with high hardness, bright and clean surface and full inner ripe degree, promoting the absorption and digestion.

- Due to high temperature and pressure inside of the pelleting chamber, common pathogenic microorganisms and parasite in the material can be killed completely, strengthening the ability of chicken to fight the disease, reducing the death rate of the chicken.

- Four kinds of powers are equipped, electric motor, diesel engine, gas engine and PTO, suitable for all economic level countries and regions including, especially the regions without enough electricity, like Nigeria.

Small Portable Poultry Pellet Mill Plant Setup Cost in Nigeria

Building a poultry feed pellet mill plant to produce high quality feed pellets can greatly reduce the cost of poultry farming or the easy way to start poultry feed pellet production business in Nigeria. (Related news: GEMCO Attended the 33rd Nigeria Lagos International Trade Fair >>)

The General Poultry Feed Pelletizing Process Includes: Raw Materials Selection - Crushing - Mixing - Pelletizing - Cooling and Screening - Weighting and Packaging.

Small Portable Poultry Feed Mill Plant for Sale

Please Note: This small poultry feed pellet production line is also suitable to make pellets for livestock, like cow/cattle, goat/sheep, pig, and fish.

The cost to set up a small poultry feed pellet production line is decided by the poultry feed pellet production process and corresponding equipment. Here are some tips on how to choose equipment for a small scale poultry feed pellet mill plant scientifically.

- Select appropriate pellet mill machine according to the raw materials and the output

- The output of the mixer is at least 1.2 times that of poultry feed mill

- The output of the poultry feed grinder is twice that of the mixer

- If the proportion of straw and straw raw materials is more than 20%, vertical mixing machine cannot be used. Screw conveying must be equipped with arch breaking device

- If the raw materials have more powder, the mixing machine should be equipped with a conveyor, it’s not recommended to use crusher for transportation directly.

As the leading manufacturer of animal feed pellet mill, GEMCO never stops to provide customers high quality equipment with factory price by continuously strengthening its R & D team. Our experienced technical engineers can quickly provide the customized plan that integrates factory design, equipment selection and more. If you are interested in more poultry feed pellet mill projects we built around the world, just contact us directly to get the project reports!

Small Scale Portable Poultry Feed Mill Machinery Works Automatically

Portable Poultry Feed Pellet Mill Enjoys High Popularity in Nigeria – Buy High Quality Portable Feed Mill for Poultry Feed Pellet Making: HOT sale portable poultry feed pellet machine in Nigeria offered by animal feed pellet mill manufacturer or supplier, guide on process of poultry feed pellet production and how to start poultry feed pellet making business with limited cost in Nigeria, Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

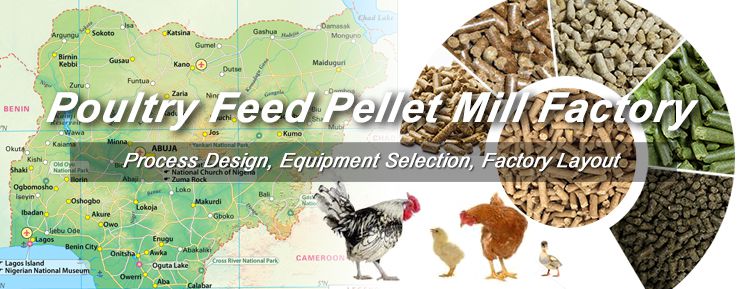

Raw Material Requirement for Poultry Feed Pellet Making

Poultry Feed Pellet Making Requirements

Many raw materials like corn, soybean, alfalfa, sorghum etc. can be used to make poultry feed pellets by animal feed pellet mill. Usually, the chicken feed is a mixture of several nutritional materials to meet the daily needing requirement of the chicken. But for different kinds of chicken, the raw material requirements are different as well.

For broiler rations. Chicken feed with high protein is more suitable for meat birds. The protein content what they need typically ranges in 18-20%. For layer ration, they need 16-18% protein and additional calcium mineral substance fro strengthen the egg shell. So, before you using this chicken feed pellet mill, you should mix the raw material based on your chicken requirement.

Raw Materials Proportion for Layer Chicken Feed

| 1 | corn/maize:58.4%, wheat bran: 3%, soybean meal: 28%, calcium hydrophosphate:1.3%, limestone:8%, salt: 0.3%, additives:1% |

|---|---|

| 2 | corn/maize:57.9%, wheat bran: 4%, soybean meal: 21.5%, fish meal: 2%, rapeseed meal: 4%, calcium hydrophosphate:1.5%, limestone:8%, salt: 0.3%, additives:1% |

| 3 | corn/maize:57.4%, wheat bran: 3%, soybean meal: 20%, fish meal: 2%, rapeseed meal: 4%, cottonseed cake: 3%, calcium hydrophosphate:1.3%, limestone:8%, salt: 0.3%, additives:1% |