Maximize Your Resources: Biomass Pellet Machine for Waste Utilization

Biofuel Making Machine Overview

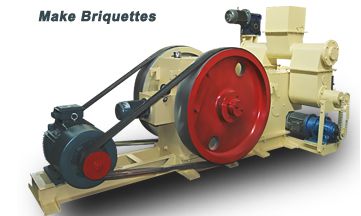

Biofuel making machine is designed and manufactured under the condition of the urgent green energy development. From the name of “biofuel”, we can see that the raw materials used for making biofuel is the biomass materials which including agro wastes like rice straws, corn stalk, rice husk, cotton stalk, sorghum stalk etc and the forestry residues like braches, leaves, leftover from the logging industry, sawdust, bamboo dust etc.

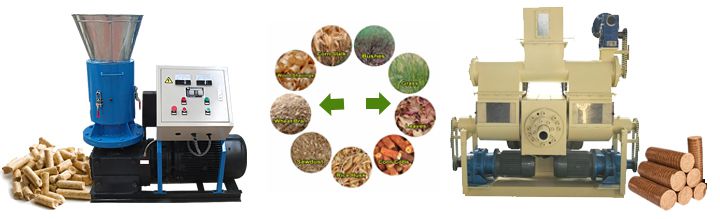

They are designed with different principles, the pellet mill for wood is developed with small size, simple structure, easy to move to everywhere, mainly producing the small cylindrical pellet with the diameter in 4-12mm; while the briquette press for sawdust is designed with more elaborate structure, mainly producing the cylindrical briquette with the diameter in 30mm-70mm, and some briquette making also can produce the pellet.

Setting Process of Biofuel Making Machine

Whether you want to make pellet or the briquette, you should know about the process of using the biofuel machine. The general process is as followed.At first, you should collect enough raw material which is mentioned above. When the raw material is ready, you need to break the raw materials into small size less than 3mm, and the moisture should be adjusted within 12%-14%. The machine you need to equip are crushing machine and dryer. The crushed materials will enter the biofuel making machine to be pressed into uniform size. Then through the cooling machine, the biofuel can stored or packed for sale. According to the different size, the final product is generally divided into two large part, which are the pellet and briquette, and the former is usually used in the small furnace, household furnace and BBQ etc, while the later is generally used for large furnace, industry boiler and power generation factory etc.

Bio fuel Making Machine Bringing Benefit to People

- The raw material used for biofuel is easy to found here and there, especially on the crop farm. Using the biofuel making machine can not only solve the problem of storing agro waste, but also produce cheap fuel for daily use.

- The produced biofuel is friendly to our environment, without bad gas produced during the combustion. And with the uniform size, the biofuel is easy to manage, store, pack and transform, saving the space and time.

- Whether you use pellet mill for wood and briquette press for sawdust, you can produce green biofuel for self daily use, such as, home heating and cooking, household furnace, BBQ, reducing the daily fuel cost.

- When you have a series of biofuel making equipment, you have the ability to produce large amount of biofuel for sale, improving the income.

- With the bright future prospect, investing biofuel making machine is an ideal project for the new investing beginners, we will offer you the details about the investment.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!