Making Peanut Husk Briquettes by Punching Briquetting Equipment

Punching Peanut Husk Briquetting Equipment Ship to India

Punching briquette equipment is popular in Kenya, Australia, UK and other countries. Recently, there is briquette machine is sending to India.In early 2019, an Indian customer made an enquiry for pelletizing or briquetting equipment. With plenty of peanut shell as raw materials and large demand for pellet fuel from the local boiler, the Indian customer would like to produce the large pellet and briquette in diameter of 8mm and 22mm for sale. Based on the raw materials, plant, power, investment and other related aspects, we customized one briquette production line for India customer.

(Peanut Shell Briquetting Equipment Leaving to India)

Briquette Machine for Processing Peanut Husk

Peanut shell consists of plenty of cellulose and lignin, very suitable for making pellets and briquettes. Due to the small size and the low moisture content, the peanut shell of this customer can enter the briquette equipment directly. If the raw material is not as small as the peanut shell, it should be crushed into small pieces then to briquette. At the same time, the moisture content of raw materials had better be kept within 15%.

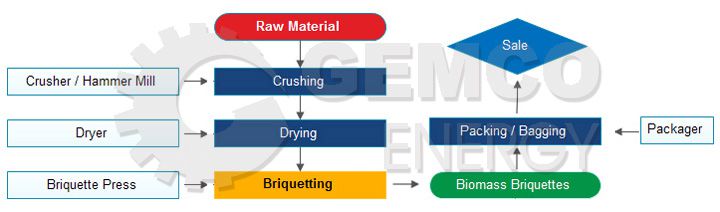

Briquetting Production Process

- Peanut Husk --> Conveyor

- Conveyor --> Silo (for storing enough raw materials to keep the continuous production )

- Silo --> Briquetting equipment (for producing 8mm/2mm diameter briquette)

- Briquetting Equipment --> Cooling machine (for decreasing the temperature of the fresh briquette from the briquette equipment)

- Cooling Machine --> Packing machine (for packing the cooled briquette into bags for sale)

Want to set up your own briquette equipment line? Contacts us please!

Punching Briquette Equipment Processing 22MM Wood Pellets/Briquettes

The raw material in the video is weed tree, using 22mm diameter die to produce briquette. The machinery type is GC-MBP-2000 Punching Briquette Equipment. The test time in site is 5 minutes, with the feature of fast briquetting and high briquette quality.

GC-MBP-2000 Punching Briquetting Equipment

GC-MBP-2000 Punching Briquetting Equipment is the machine for producing the crushed biomass raw materials including plant straw, grain shells, peanut meal (shell), sawdust, sawdust, bamboo powder, wood scraps, forest residues, domestic waste etc into briquettes. The punching briquetting machine manufactured by GEMCO is featured with wide adaptability of materials, able to produce the briquette in diameter from 8mm to 70 mm.

| Model | Output(gk/h) | Size (mm) | Weight (kg) | Total Power (kw) | Finished Fuel Rod's Diameter (mm) |

|---|---|---|---|---|---|

| GC-MBP-2000 | 950-1200 | 3500*2000*1800 | 7000 | 65 | 8/10/22/70 |

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!