Guidance on Professional Wood Pellet Production

Wood and Wood Business

Wood, as one kind of raw material for processing, is featured with light weight, strong heavy than high, good resilience, easy processing and impact resistance, thus having been listed as an important raw material since ancient times. And wood processing industry has been lying a crucial role in the civil economic development as well.

Traditionally, people always use the wood to make the converted timber like pole, mine timber, sleeper etc artificially, with the development of age, the wood products has been transformed from the converted timber to the more sophisticated processing, like plywood, fiber board, chipboard for produce industrial and commercial furniture, carved furniture, boat furniture etc, thus forming wood processing into the independent and complete wood processing industrial system.

Wood Bringing New Energy

We all know that new energy is called relative to conventional energy, also called non-conventional energy. Under the new technology and new materials, even the traditional resources can have opportunity to modernly develop and use as new energy resource. As one kind of new energy, biomass energy is coming to public’s view gradually, in which the wood pellet production is the most popular. Wood pellet production generally relies on the residues produce from wood processing.

The final products is widely used for home heating and cooking, public heating, industrial heating, industrial boiler, pellet stove, green house heater, cooling device, small steam boiler, hot spa etc.

Wood Pellet Production Around the World

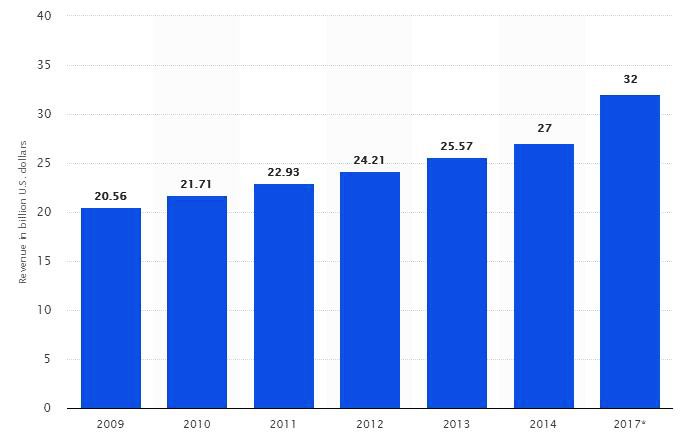

At the same time, with the development of renewable energy technology, wood trade for wood pellet production is taking a big part in the world. Producing wood pellet develops rapidly since 2000 with the wood pellet output reaching to 1100 tonnes, which means that wood pellet is more and more popular around the world.

In north America, as of 2012, there are 42 wood pellet production plants have been built in Canada with 3 million tonnes per year; in USA, the demand for wood pellet of people is also increasing more and more, the wood pellet production has increased from 1.8 tonnes in 2008 to 7.4 tonnes in 2015.

In Europe, the demand for wood pellet in the 28 EU countries has reached to 20.3 million tons in 2015 which taking up 6% of the total solid biomass materials. And the wood pellet production in the EU member countries has reached to 14.1 million tons, taking up 70% of their demand. That data is from the “AEBIOM Statistical Report 2016” issued by the European Biomass Association (AEBIOM).

At the same time, in the developing countries with rich biomass materials like African countries, Indonesia, Malaysia, Vietnam etc, due to rich agricultural and forestry residues exist, the wood pellet production has been increasing year by year as well.

GEMCO Wood Pellet Production Projects

As the professional wood pellet producing machinery manufacturer, we have built projects for wood pellet production successfully all over the world. Such as,- Bamboo Pellet Mill Plant for Ghana

- 20ton/H Wood Pellet Plant in Vietnam

- 3.6-4.5TPH Complete Wood Pellet Line in Morocco

- 500kg Per Hour Biomass Briquetting Plant in Russia

- 2 Ton Per Hour Wood Pellet Plant in Australia

- 3ton/D Licorice Briquette Plant in Tajikistan

Wood Pellet Production Details

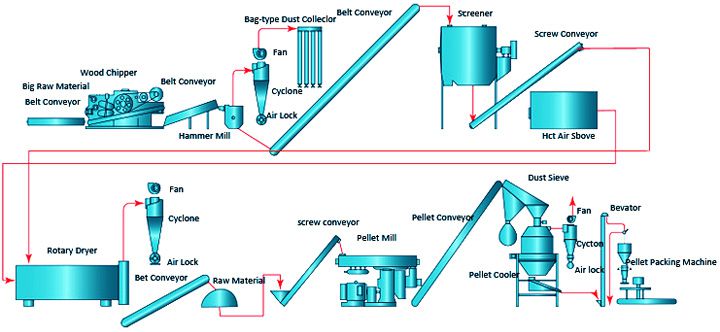

Speaking of wood pellet production, the most important thing is the processing. To be generally, the wood pellet production mainly consists of chipping processing, crushing processing, drying processing, pelleting& briquetting processing, cooling processing, packing processing and conveying processing.

(Wood Pellet Production Process)

After the preparation processing, pelleting processing is ready, the pelleting machine or briquetting machine can start to work. About choosing the machine, you have to according your raw materials condition, actual situation and final product applications.

When the wood pellet is finished, it has high temperature needing to be cooled for later better packing and storing. Cooling machine with sieve can separate the dust or breaking pellets from the well formed pellet to re-pelleting, while the well formed wood pellet will enter to the next auto packing processing.

The whole wood pellet production processing is not exactly the same in different countries and regions, just like the wood pellet making line mentioned above, they have many differences in every each projects. And we have the ability to customize the most suitable and professional machinery for your wood pellet production.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!